"W-Sn" Plating For Higher Bending Performance

COF (Chip On Film), with its thin structure and high bendability, is widely used in Display driver modules for FPD (Flat Panel Displays). As the frame bezel of the displays becomes narrower, the demand for COF with smaller bending radius for higher bendability is increasing.

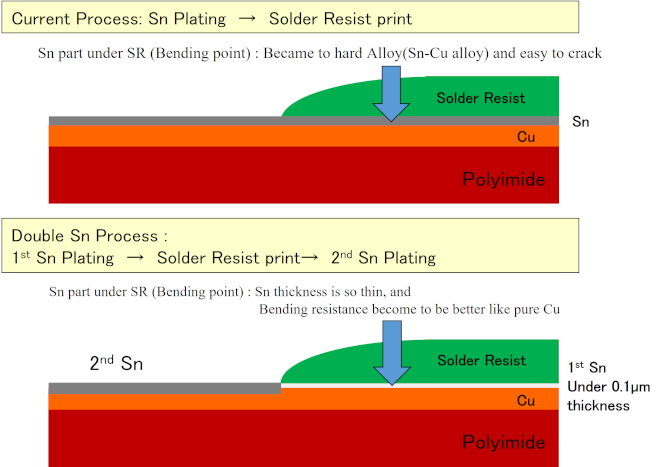

A typical COF process applies Tin (Sn) plating on the surface of the formed circuit pattern, and then solder resist covering is applied to protect the circuit wiring.

Due to the thermal history added during the assembly process where the COF is mounted on the driver unit, the Tin diffuses into the copper wiring, resulting to form an alloy which reduces the bending performance.

However, by applying our “W-Sn (double Tin) ” plating process, where a primary thin Sn plating layer would be applied on the wiring and then a 2nd layer of Sn plating will be applied on to the bonding areas after the Solder Resist process, enables us to achieve high bending flexibility because the area under the solder resist, where the wiring is to be bent, is thinly plated.

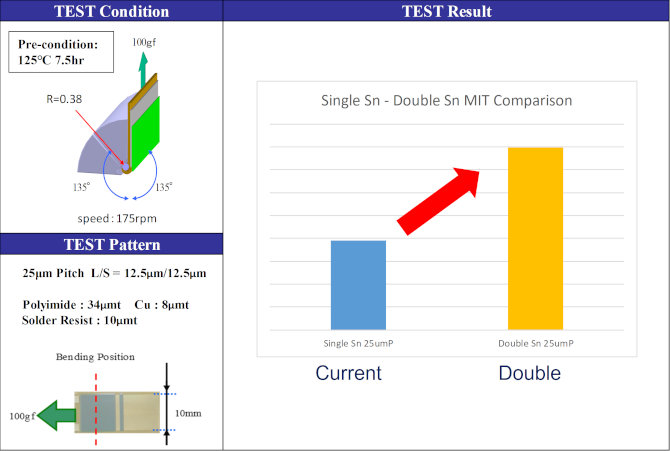

In the MIT test, the bending strength is more than twice as high as that of conventional products.

MIT Test Result

MIT Test Result

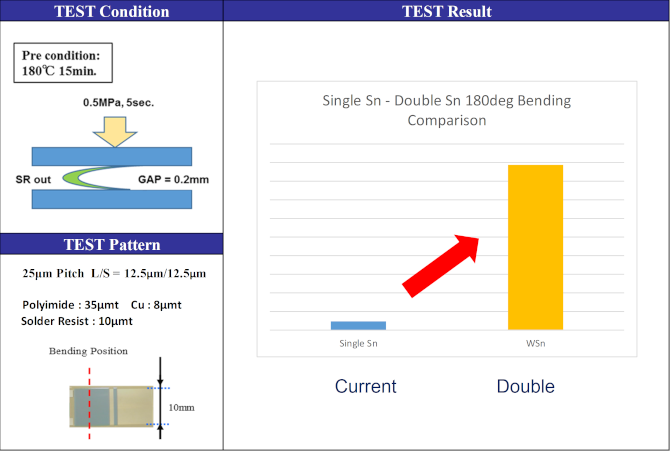

Push Test Result

Push Test Result